Henan Zhongke Engineering & Technology Co., Ltd. is an import and

export company, which is specialized in mining machinery,

metallurgical machinery and building materials equipment

manufacturing. The head quarter located in Zhengzhou High-Tech

zone.The company business scope include: jaw crusher, impact

crusher, hammer crusher, cone crusher, ball mill, rod mill, ceramic

ball mill, vibrating feeder, vibrating screen, belt conveyor,

mineral ore separating machine, magnetic separator, flotation

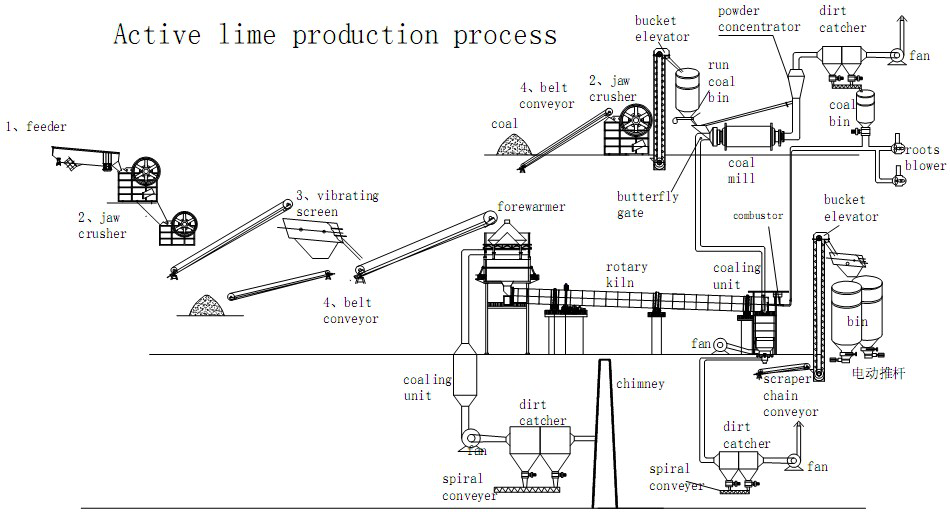

machine, classifier, spiral chute, rotary dryer, rotary kiln. We

also can offer sand and stone production line, crushing and

grinding plant, ore beneficiation line, A A C (aerated concrete

block) production plant, small cement plant, active lime production

line and so on.

We pay attention to basic management, build enterprises quality

management system; the work site realizes fixation management; the

logistic enjoys ABC management; the office achieves computer

automatization; the product development process design adopts C A

D, C A P P technology. Zhongke Machinery can provide high quality

products, as well as customized optimized technical proposal and

one station after-sale service.

The company machine quality and service help us gain reputation in

the mining machines market. So far we have exported to Canada,

Ecuador, Indonesia, Nepal, India, Russia, Uzbekistan, Honduras,

Zimbabwe, Nigeria, Malawi, and the business keeps expanding.

Welcome to Henan Zhongke factory!